STUDIO PROCESS

Outputting Film Positives

Each individual colour layer, including various textures or tones of a colour, are exported to an inkjet printer which produces a high contrast dense black positive on film.

Drying Screens

Coated screens are placed in a heated air drying cabinet to accelerate the drying process.

Exposing the Screen in the Vacuum Frame

The film positive is placed in contact with the screen under vacuum to provide perfect contact during exposure.

Printing Individual Colours in Registration

Each colour is printed to paper using a registration system which allows exact repositioning of the sheet each time a new colour is added. This means that each colour is always in exactly the same position on every sheet as more colours are added thereby ultimately producing multiple identical copies of the same piece of artwork.

Producing Multiple Copies from each Screen

Any number of copies can then be produced, one colour component at a time, one sheet at a time. So 23 copies of a print with 20 colour elements requires 460 passes of screens over all sheets to complete the edition.

Limited Editions

Only a set number of prints is produced. The quantity is indicated on the left side under the image and below the order in which the particular print was produced (eg 3/23 - the third print in a quantity of 23).

Prints produced on printing machines by the thousand are not limited edition prints, have little intrinsic value and are prone to fade with time.

Limited Edition silk screen prints are produced one at a time in an intensely manual process. Because there is a limited number of copies produced, fine art original prints can be sold at very reasonable prices.

Creating the Black Key Line

The Microsoft Surface computer allows me to draw freehand directly to the screen and create the base black keyline. I also use various brushes to add texture and soft edges in Photoshop. I create a separate layer for each colour or texture for outputting to film positives.

Coating Screens with Emulsion

In safelight conditions the required number of screens are coated with several coats of light sensitive emulsion on both sides to prepare the screens for exposure of the film positives.

Locating Positive on Screen prior to Exposure

Each positive is accurately centred on the screen before exposure to simplify the positioning of the image on the paper sheet when printing commences.

Developing the Screen

After exposure the screen is washed out to dissolve the unexposed sections of the screen emulsion. The image is now effectively a "negative" version of the design. It reverts to a "positive" when ink is pushed through the screen onto paper.

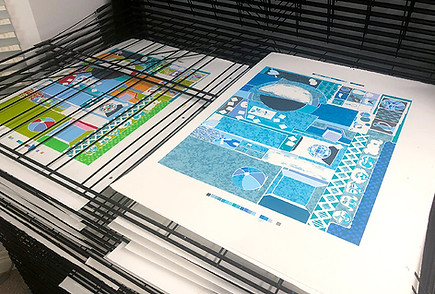

Progressive Printing of Colours One by One

A colour component of the design is printed to each sheet in succession so that particular element is completed on all copies before the next element is introduced via a new critically registered screen.

Printing the Black Key Line

The last screen printed is the black key line which masks fine colour overlaps which occur during printing but also adds unity and definition to the final image. The parallel with Japanese woodblock printing is complete.